- Technologies

A glimpse of the Dinex Technology Division

At Dinex we strive to live up to one of our core values stating that there are always more than 1 given solution, and we are ALWAYS ready to go the extra mile to support our customers. We want our customers to find Dinex easy to do business with.

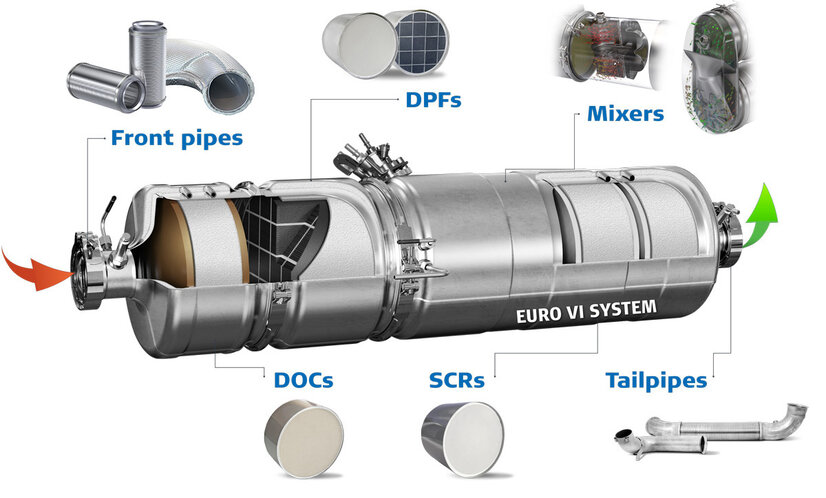

Product Portfolio - Customized Innovations

Full System and customer specific engineering approach: From final application down to coating formula.

Catalyst coatings for diesel, natural gas & H2 engines

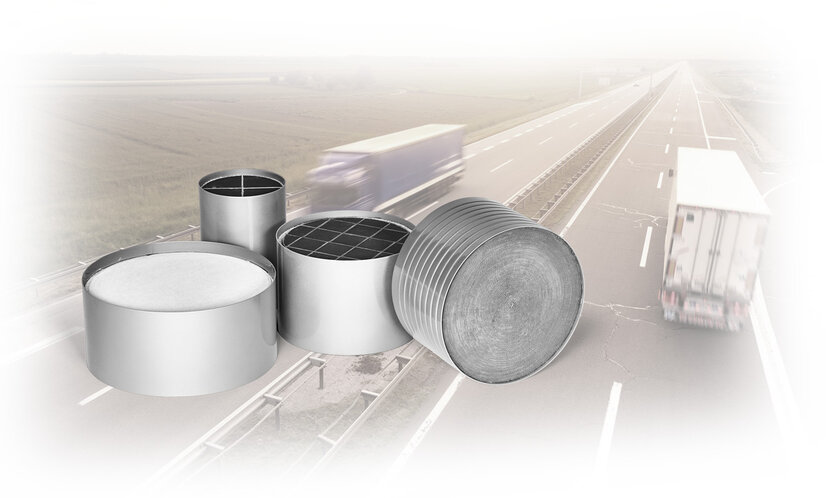

Diesel particulate filters High Porosity SiC filters & metallic substrates

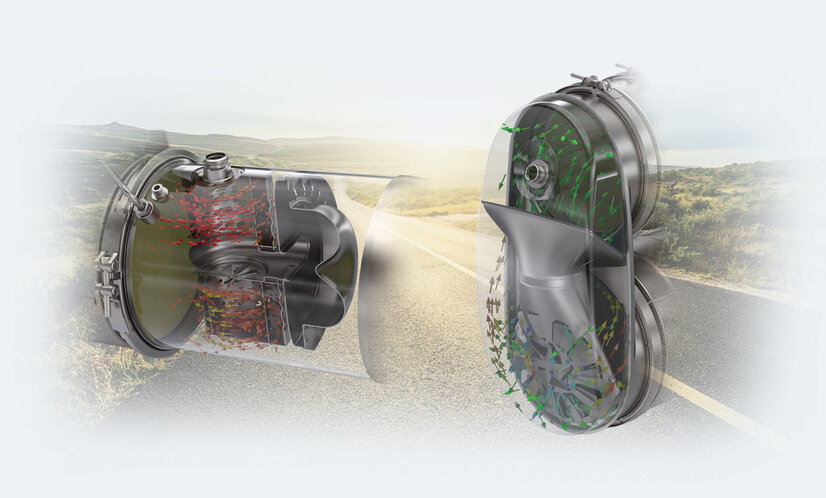

Canning and system integration with optimal flow and urea mixing

Front pipes, downstream pipes, insulation, clamps & decoupling

Full Systems

Full Innovation & Test Facilities

Own tools, laboratories, prototyping capabilities and test facilities to develop and validate in-house ATS technologies.

NVH, CFD, FEA simulations

Coating analysis labs

Coating test labs (lab scale)

Catalyst modelling

Prototyping

Hot shaker testing

Deposit testing on heater/blower

Medium and Heavy-Duty Engine dynamometers

Coating technologies

Developed in-house, are IP protected, Euro VI / Stage V compatible and proven in the field.

Diesel Oxidation Catalyst (DOC)

Diesel Particulate Filter (DPF)

Selective Catalytic Reduction (SCR - Cu-Ze)

Selective Catalytic Reduction (V-SCR)

Ammonia slip catalyst (ASC)

Three-Way Catalyst (TWC)

Methane Oxidation Catalyst (MOC)

Mixing technologies

Developed in-house using own methods, are IP protected, Euro VI / Stage V compatible, compatible with airless & air-assisted urea nozzles and proven in the field.

Inline compact mixer

Inline swirl mixer

L-shape swirl mixer

Pipe mixer

U-shape impact mixer

U-shape swirl mixer

Future technologies

Dinex is preparing the future with a multitude of powertrains.

Euro 7 pre-box with e-heater

Euro 7 main-box

Hydrogen ICE

Fuel Cell technologies (Catalyst coated membranes & heated exhaust pipes)